工業(yè)涂裝流水線:噴塑線是啥?3分鐘看懂它為啥成了工廠香餑餑

提起 “給金屬穿衣服”,你可能會(huì)想到刷油漆 —— 工人用刷子蘸上油漆,再一層層地涂在鐵框或機(jī)箱等表面。然而,如今許多工廠已采用噴塑涂裝流水線,這種技術(shù)不僅將效率提升不少,還能使金屬涂層更加耐用。

When it comes to "dressing metal", you may think of painting - workers dip a brush into the paint and apply it layer by layer to surfaces such as iron frames or chassis. However, nowadays many factories have adopted spray coating assembly lines, which not only improve efficiency but also make metal coatings more durable.

那這噴塑涂裝流水線到底是啥?其實(shí)是一個(gè)自動(dòng)化的“穿衣”工藝流程。首先,對(duì)金屬零件進(jìn)行清潔,以去除表面的油污和銹跡;再給它噴上一層像面粉一樣細(xì)的塑料粉末,最后將金屬零件置于高溫“烘烤”設(shè)備中,使塑料粉末融化并形成光滑的保護(hù)層,牢牢附著在金屬表面。整個(gè)過(guò)程可以類比為蛋糕裝飾的步驟:先清理干凈蛋糕胚,然后撒上糖霜,最后通過(guò)烘烤定型。然而在這里,“蛋糕”指的是金屬件,而“糖霜”則是塑料粉末。

What exactly is this spray coating assembly line? It is actually an automated 'dressing' process. Firstly, clean the metal parts to remove surface oil stains and rust; Spray it with a layer of plastic powder as fine as flour, and finally place the metal parts in a high-temperature "baking" device to melt the plastic powder and form a smooth protective layer, firmly adhering to the metal surface. The entire process can be likened to the steps of cake decoration: first clean the cake embryo, then sprinkle icing sugar, and finally bake it to shape. However, here, 'cake' refers to metal pieces, while 'frosting' is plastic powder.

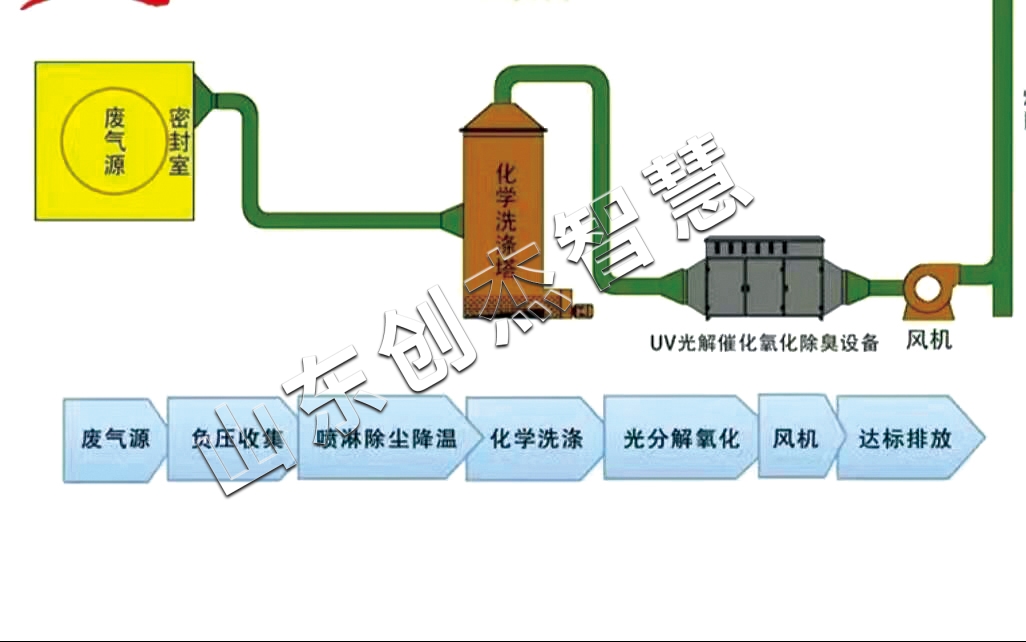

傳統(tǒng)的油漆作業(yè)需要工人佩戴防護(hù)口罩以避免吸入甲醛,涂抹完成后還需等待數(shù)天干燥,遇到潮濕陰雨天氣甚至可能出現(xiàn)霉變。而如今,全自動(dòng)化的噴涂生產(chǎn)線只需將零件放入設(shè)備,數(shù)小時(shí)后即可完成處理,工人只需看著設(shè)備運(yùn)行即可。其次,其耐久性極佳。我們?nèi)粘J褂玫姆辣I窗、電動(dòng)車(chē)車(chē)架等產(chǎn)品大多采用噴塑工藝,很多都是噴塑的,就算風(fēng)吹雨淋,幾年都不會(huì)掉皮生銹,相較之下,油漆涂層可能沒(méi)多久就會(huì)出現(xiàn)脫落問(wèn)題。 另外,這種工藝還具備環(huán)保優(yōu)勢(shì)。與含有大量有害氣體的油漆不同,噴塑使用的粉末可回收再利用,不僅減少了浪費(fèi),還不會(huì)釋放有毒氣體。在環(huán)保要求日益嚴(yán)格的背景下,許多工廠選擇升級(jí)到噴塑流水線也是為了避免環(huán)保處罰。

Traditional painting operations require workers to wear protective masks to avoid inhaling formaldehyde, and after application, they need to wait for several days to dry. In humid and rainy weather, mold growth may even occur. Nowadays, fully automated spraying production lines only need to put the parts into the equipment and complete the processing after a few hours. Workers only need to watch the equipment run. Secondly, it has excellent durability. Most of the anti-theft windows, electric vehicle frames, and other products we use in our daily lives use spray painting technology, and many of them are spray painted. Even if exposed to wind and rain, they will not peel or rust for several years. In contrast, paint coatings may not peel off soon. In addition, this process also has environmental advantages. Unlike paints that contain a large amount of harmful gases, the powder used for spraying can be recycled and reused, which not only reduces waste but also does not release toxic gases. In the context of increasingly strict environmental requirements, many factories choose to upgrade to spray painting assembly lines to avoid environmental penalties.

簡(jiǎn)單說(shuō),噴塑流水線就是工廠里的 “金屬美容師”,不僅效率高、效果佳,還兼具環(huán)保特點(diǎn),這也是吸引眾多企業(yè)愿意花錢(qián)買(mǎi)它。

Simply put, the spray coating assembly line is like a "metal beautician" in a factory. It is not only efficient and effective, but also environmentally friendly, which attracts many companies to spend money on it.

我們是有著三十多年的行業(yè)經(jīng)驗(yàn)的源頭廠家,我們的粉末靜電噴涂設(shè)備憑借其先進(jìn)的技術(shù)、優(yōu)質(zhì)的產(chǎn)品和專業(yè)的服務(wù),贏得了廣大客戶的認(rèn)可和好評(píng)。從原材料采購(gòu)到成品出廠,每一個(gè)環(huán)節(jié)都經(jīng)過(guò)嚴(yán)格把控質(zhì)量,更是我們對(duì)每一位客戶的承諾,確保產(chǎn)品達(dá)到最優(yōu)狀態(tài),讓大家買(mǎi)的安心用著放心。

We are a source manufacturer with over 30 years of industry experience. Our powder electrostatic spraying equipment has won the recognition and praise of our customers with its advanced technology, high-quality products, and professional services. From raw material procurement to finished product delivery, every link undergoes strict quality control, which is our commitment to every customer, ensuring that the products reach the best state and allowing everyone to buy with peace of mind and use them with peace of mind.

本文由 工業(yè)涂裝流水線 友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.qzxcdz.com/ 真誠(chéng)的態(tài)度.為您提供為全面的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from the industrial painting assembly line For more related knowledge, please click http://www.qzxcdz.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:自動(dòng)噴砂房操作規(guī)范與安全要點(diǎn)指南

下一篇:

相關(guān)產(chǎn)品

相關(guān)新聞

-

伸縮式噴漆房在大中型機(jī)械設(shè)備中的應(yīng)用

-

噴漆房易損件、消耗件更換方法

-

河北水旋式噴漆房+催化燃燒廢氣處理項(xiàng)目介紹

-

要用好VOCs廢氣處理設(shè)備,必須做好設(shè)備的維護(hù)保養(yǎng)!

-

濾筒除塵器使用及維護(hù)方法分享

-

有機(jī)廢氣處理中,常用的活性炭分類及性能分析

-

移動(dòng)伸縮式噴漆房設(shè)備設(shè)計(jì)、安裝技術(shù)分析

-

移動(dòng)伸縮式噴漆房如何選擇廢氣處理方式?

-

分享篇——伸縮噴漆房結(jié)構(gòu)及功能解析

-

布袋式除塵器使用過(guò)程中的注意事項(xiàng),你知道嗎?

魯公網(wǎng)安備 37142502000144號(hào)

魯公網(wǎng)安備 37142502000144號(hào)