自動式拋丸機核心原理及核心構成講解

自動式拋丸機是通過機械方式將彈丸高速投射到工件表面,實現清理、強化或預處理的設備,其核心原理是利用高速運動的彈丸(速度 50-80m/s)與工件表面的沖擊摩擦,去除氧化皮、銹跡、油污等雜質,同時改變表面粗糙度(形成 0.5-50μm 的凹凸紋理),廣泛應用于機械制造、汽車零部件、鋼結構等領域,是表面處理環節的高效自動化裝備。

Automatic shot blasting machine is a device that uses mechanical means to project projectiles at high speed onto the surface of a workpiece, achieving cleaning, strengthening or pre-treatment. Its core principle is to use the impact friction between the high-speed moving projectile (speed 50-80m/s) and the workpiece surface to remove impurities such as oxide scale, rust, oil stains, etc., while changing the surface roughness (forming a 0.5-50 μ m concave convex texture). It is widely used in mechanical manufacturing, automotive parts, steel structures and other fields, and is an efficient automation equipment in the surface treatment process.

工作原理的核心是 “動能傳遞 - 表面作用 - 物料分離” 的連續過程。設備啟動后,彈丸由儲丸箱進入拋丸器(核心部件),通過葉輪的高速旋轉(轉速 1500-3000r/min)獲得動能,經定向套引導形成扇形射流,均勻覆蓋工件表面。彈丸沖擊工件時,一方面通過沖擊力剝離表面附著物(如鑄件的型砂、鍛件的氧化皮),另一方面通過反復塑性變形使工件表層產生殘余壓應力(深度 0.1-1mm),提升材料疲勞強度(提升 20%-30%)。處理后的彈丸與雜質混合物落入底部輸送裝置,經篩分系統分離 —— 合格彈丸(粒徑偏差≤5%)返回儲丸箱循環使用,雜質(如銹渣、粉塵)則進入廢料收集箱,實現彈丸回收率≥95%,減少物料消耗。

The core of the working principle is the continuous process of "kinetic energy transfer surface interaction material separation". After the equipment is started, the pellets enter the shot blasting machine (core component) from the storage box, and obtain kinetic energy through the high-speed rotation of the impeller (speed 1500-3000r/min). They are guided by the directional sleeve to form a fan-shaped jet, which uniformly covers the surface of the workpiece. When a projectile impacts a workpiece, on the one hand, it peels off surface attachments (such as casting sand and forging oxide skin) through impact force, and on the other hand, it generates residual compressive stress on the surface of the workpiece through repeated plastic deformation (depth 0.1-1mm), improving material fatigue strength (by 20% -30%). The processed pellets and impurity mixture fall into the bottom conveying device and are separated by the screening system. Qualified pellets (with a particle size deviation of ≤ 5%) are returned to the pellet storage box for recycling, while impurities (such as rust and dust) enter the waste collection box, achieving a pellet recovery rate of ≥ 95% and reducing material consumption.

自動控制系統實現全流程無人化操作,確保處理一致性。通過可編程控制器預設處理參數(如拋丸時間 10-180 秒、工件移動速度 0.5-5m/min),適應不同材質(鋼、鋁、鑄鐵)與尺寸的工件。傳感器實時監測彈丸流量、拋丸器電流、工件位置,當檢測到彈丸不足時,自動啟動補丸裝置;工件位置偏移時,輸送系統自動糾偏(調整幅度 ±5mm);處理時間達到設定值后,自動停止拋丸并觸發工件出料,整個過程無需人工干預,批次處理的表面粗糙度偏差≤2μm,遠低于人工操作的 10μm。

The automatic control system realizes unmanned operation throughout the entire process, ensuring consistency in processing. By presetting processing parameters through a programmable controller (such as shot blasting time of 10-180 seconds, workpiece movement speed of 0.5-5 m/min), it can adapt to workpieces of different materials (steel, aluminum, cast iron) and sizes. Sensors monitor the real-time flow rate of pellets, the current of the shot blasting machine, and the position of the workpiece. When insufficient pellets are detected, the shot replenishment device is automatically activated; When the workpiece position deviates, the conveying system automatically corrects the deviation (adjustment amplitude ± 5mm); After the processing time reaches the set value, the shot blasting will automatically stop and trigger the workpiece discharge. The entire process does not require manual intervention, and the surface roughness deviation of batch processing is ≤ 2 μ m, far lower than the 10 μ m manually operated.

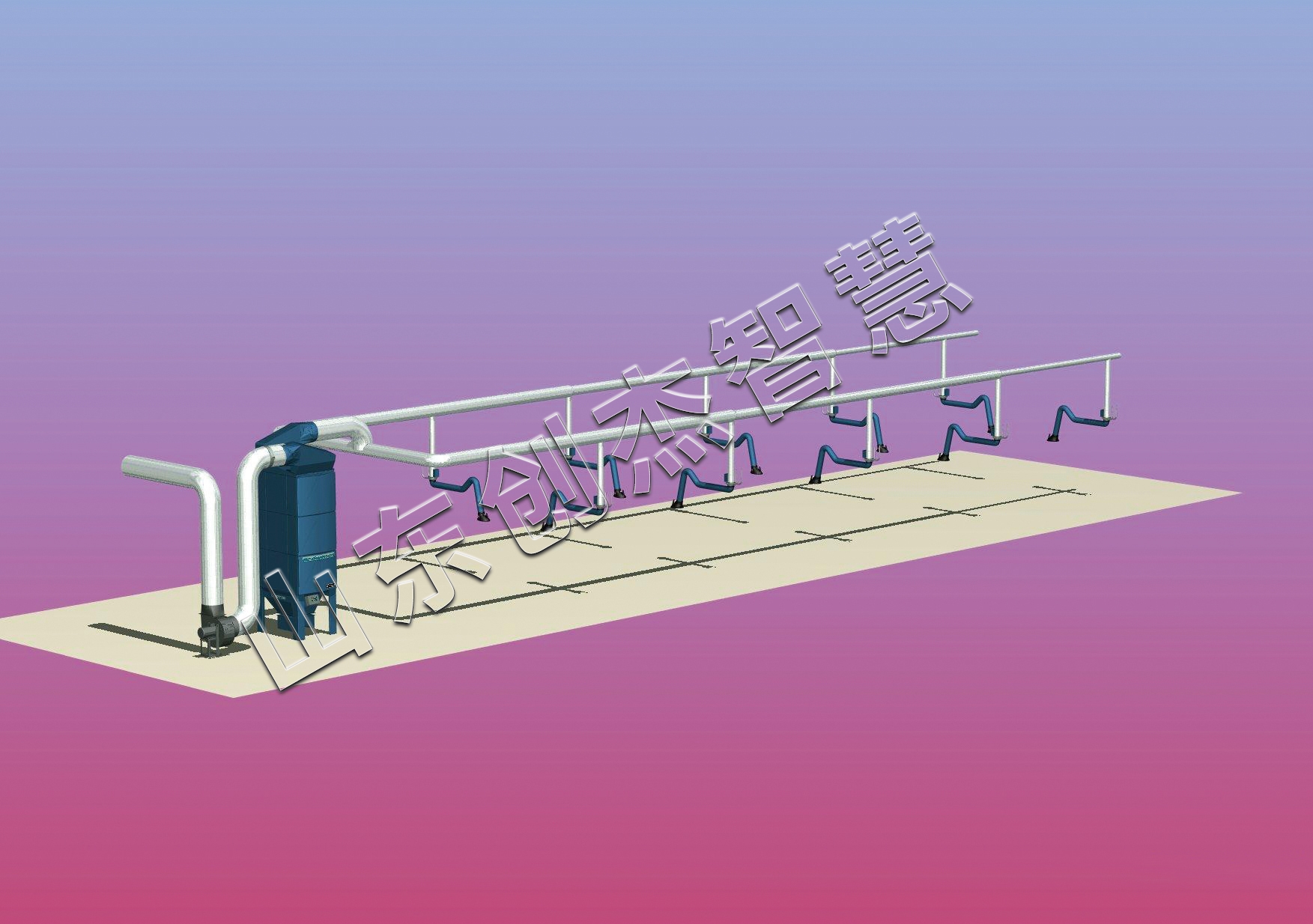

核心部件的適配設計決定設備性能。拋丸器的葉輪采用高鉻鑄鐵材質(硬度 HRC60-65),耐受彈丸長期沖擊,使用壽命可達 800-1500 小時;定向套通過調整角度(0°-30°)控制彈丸投射范圍,確保覆蓋均勻(覆蓋率≥98%)。輸送裝置根據工件形態選擇不同類型:懸掛式適合大型工件(如車架),通過吊鉤帶動工件在拋丸區旋轉(360° 無死角);輥道式適合平板類工件(如鋼板),通過輥子的同步轉動實現連續進給;履帶式適合小型零件(如螺栓),通過履帶翻轉使工件全方位受丸。

The adaptive design of core components determines equipment performance. The impeller of the shot blasting machine is made of high chromium cast iron material (hardness HRC60-65), which can withstand long-term impact of bullets and has a service life of up to 800-1500 hours; The directional sleeve controls the projectile projection range by adjusting the angle (0 ° -30 °) to ensure uniform coverage (coverage rate ≥ 98%). The conveying device selects different types according to the shape of the workpiece: suspended type is suitable for large workpieces (such as frames), and the workpiece is rotated in the shot blasting area through a hook (360 ° without dead corners); Roller conveyor is suitable for flat workpieces (such as steel plates), and continuous feeding is achieved through synchronous rotation of the rollers; Crawler type is suitable for small parts (such as bolts), which can be rotated by the caterpillar to make the workpiece receive pellets in all directions.

適應性強是其顯著特點,可應對復雜表面與多樣需求。針對高要求的精密部件(如發動機曲軸),采用多工位拋丸(2-4 個拋丸器從不同角度投射),確保油孔、凹槽等隱蔽部位的清理效果;對薄板材(厚度<3mm),通過降低彈丸速度(≤60m/s)和縮短處理時間,避免變形(變形量≤0.1mm/m)。設備還可集成后續工序,如拋丸后直接進行噴涂前的磷化處理,或與烘干設備聯動,形成 “處理 - 防護” 一體化生產線,減少工序轉換時間(提升效率 30%-50%)。

Strong adaptability is its prominent feature, which can cope with complex surfaces and diverse needs. For high precision components such as engine crankshafts, multi station shot blasting (2-4 shot blasting machines projected from different angles) is used to ensure the cleaning effect of hidden parts such as oil holes and grooves; For thin sheets (thickness<3mm), deformation (deformation amount ≤ 0.1mm/m) can be avoided by reducing the projectile velocity (≤ 60m/s) and shortening the processing time. The equipment can also integrate subsequent processes, such as direct phosphating treatment before spraying after shot blasting, or linkage with drying equipment to form an integrated production line of "treatment protection", reducing process conversion time (improving efficiency by 30% -50%).

運行過程的環保設計符合清潔生產要求。設備采用全封閉結構(艙體密封等級 IP65),防止彈丸飛濺與粉塵外泄(粉塵濃度≤5mg/m);內置的除塵系統(如濾筒除塵器)通過負壓收集處理過程中產生的粉塵(收集效率≥99%),凈化后的空氣直接排放;彈丸添加與廢料清理采用密封式設計,避免人工接觸造成的職業健康風險。這種設計使設備運行時的噪音控制在 85dB 以下(符合工業場所標準),滿足環保與安全規范。

The environmentally friendly design of the operation process meets the requirements of clean production. The equipment adopts a fully enclosed structure (cabin sealing level IP65) to prevent projectile splashing and dust leakage (dust concentration ≤ 5mg/m); The built-in dust removal system (such as filter cartridge dust collector) collects and processes the dust generated during the process through negative pressure (collection efficiency ≥ 99%), and the purified air is directly discharged; The projectile addition and waste cleaning adopt a sealed design to avoid occupational health risks caused by manual contact. This design ensures that the noise level during equipment operation is controlled below 85dB (in compliance with industrial standards), meeting environmental and safety regulations.

自動式拋丸機通過自動化控制與高效沖擊原理,實現了表面處理的質量穩定、成本可控與環境友好,其特點既體現在對復雜工件的適應性上,也反映在與現代生產線的兼容性上。隨著智能制造的發展,設備正朝著更精準的參數控制(如根據工件材質自動匹配彈丸類型與速度)、更全面的信息反饋(如處理效果的在線檢測)方向升級,為工業產品的表面質量提升提供更可靠的技術支撐。

The automatic shot blasting machine achieves stable quality, controllable cost, and environmentally friendly surface treatment through automation control and efficient impact principles. Its characteristics are reflected not only in its adaptability to complex workpieces, but also in its compatibility with modern production lines. With the development of intelligent manufacturing, equipment is upgrading towards more precise parameter control (such as automatically matching projectile types and speeds based on workpiece materials) and more comprehensive information feedback (such as online detection of processing effects), providing more reliable technical support for improving the surface quality of industrial products.

本文由自動式拋丸機友情奉獻.更多有關的知識請點擊:http://www.qzxcdz.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.qzxcdz.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

上一篇:安裝焊煙除塵設備:這些事項要注意

下一篇:自動噴砂房的核心原理及主要用途

魯公網安備 37142502000144號

魯公網安備 37142502000144號