機器人涂裝線使用噴涂機器人掃“盲區”!工作效率提升4至8倍機器人涂裝線使用噴涂機器人掃“盲區”!工作效率提升4至8倍

在珠海深水裝備制造基地涂裝車間內,外壁噴涂機器人在滾輪架協同下沿著塔筒精準游走,噴頭均勻吐出油漆;不久后,塔筒內部,內壁噴涂機器人與智能履帶式接駁車默契配合,自動協調、同步運行。

In the painting workshop of Zhuhai Deepwater Equipment Manufacturing Base, the outer wall spraying robot moves precisely along the tower under the cooperation of the roller frame, and the nozzle evenly sprays paint; Soon after, the spraying robot on the inner wall of the tower cooperated seamlessly with the intelligent tracked shuttle, automatically coordinating and synchronously operating.

整個過程銜接絲滑,塔筒原本粗糙的金屬表面披上了光滑如鏡的涂層。這是涂裝領域設備升級成果正式投用的現場實景,通過智能協同動態調整噴涂參數,產線將膜厚均勻性能誤差控制在±5%,工作效率較傳統方式提升4至8倍。

The entire process is seamlessly connected, and the rough metal surface of the tower is coated with a smooth mirror like coating. This is a real-life scene of the official deployment of equipment upgrades in the field of painting. Through intelligent collaborative dynamic adjustment of spraying parameters, the production line controls the performance error of film thickness uniformity within ± 5%, and improves work efficiency by 4 to 8 times compared to traditional methods.

“過去,大型塔筒內部兩端各2500毫米的盲區需人工進入噴涂,耗時長,且存在難以噴涂的死角。現在我們以‘機進管’代替‘人進管’,既消風險又提效。”涂裝產線技術負責人張海鵬介紹道。

In the past, the blind spots of 2500 millimeters at both ends inside large tower tubes required manual spraying, which was time-consuming and had difficult to spray blind spots. Now, we are replacing 'manual pipe entry' with 'machine entry', which not only reduces risks but also improves efficiency, "said Zhang Haipeng, the technical director of the painting production line.

涂層如同海洋油氣裝備的防腐“鎧甲”。涂裝環節直接關系著裝備防海水腐蝕、鹽霧侵蝕和生物附著的能力。為解決傳統涂裝時漆膜厚度不穩定、作業效率低、能耗較高等問題,聯合國內頭部廠家攻關,在涂裝產線中創新應用十余項新技術,自主研發智能履帶式接駁車,構建覆蓋涂裝全過程的智能化控制模式。

The coating is like the anti-corrosion "armor" of marine oil and gas equipment. The painting process directly affects the equipment's ability to resist seawater corrosion, salt spray erosion, and biological adhesion. To solve the problems of unstable paint film thickness, low operational efficiency, and high energy consumption in traditional painting, we have collaborated with leading domestic manufacturers to innovate and apply more than ten new technologies in the painting production line. We have independently developed intelligent track type shuttle cars and built an intelligent control mode covering the entire painting process.

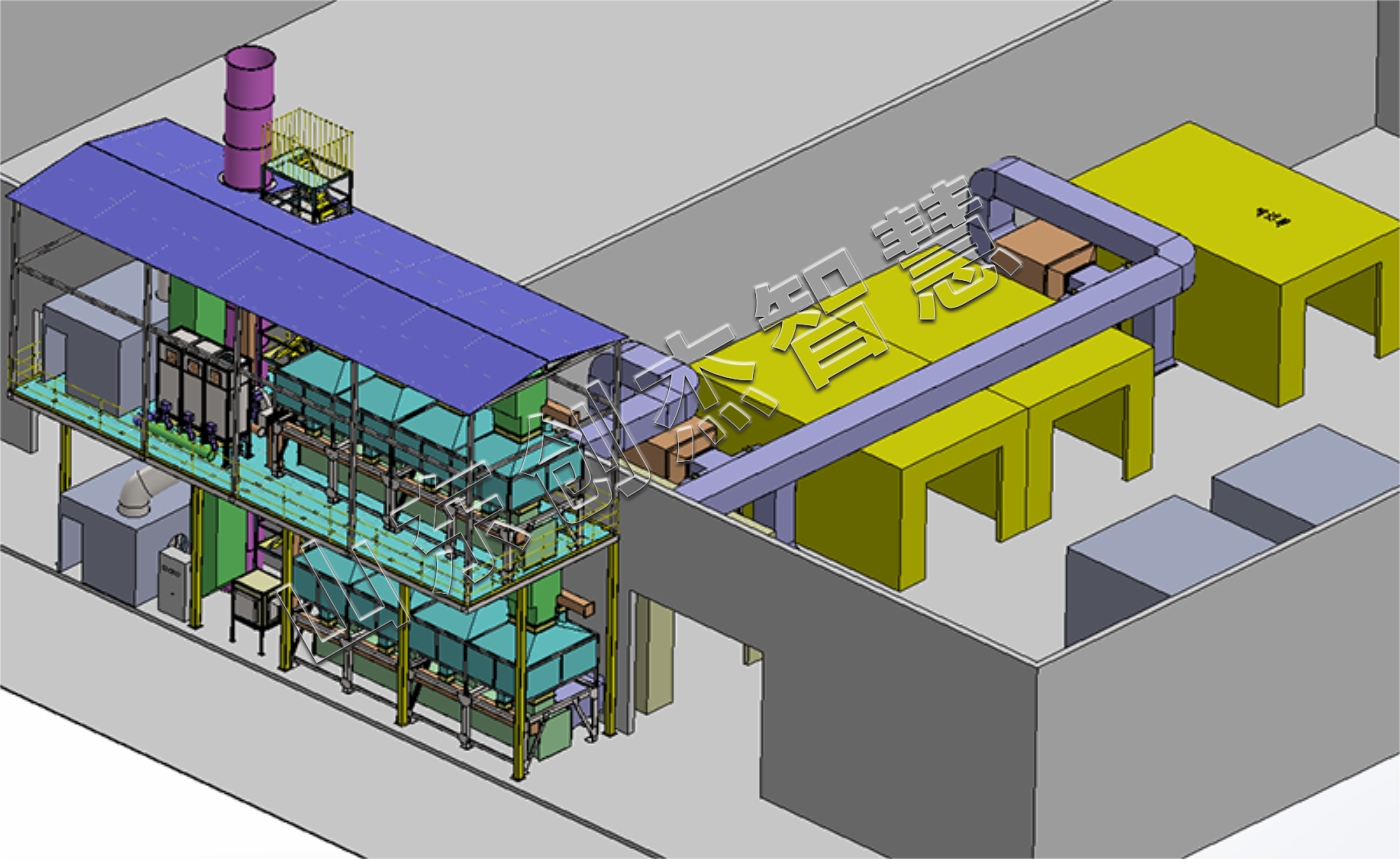

該涂裝產線整合了外壁噴涂機器人、內壁噴涂機器人、智能履帶式接駁車、滾輪架等設備協同工作。其中,外壁噴涂機器人具備自主編程、人工示教、自動避障等功能,可根據構件尺寸定制涂裝程序,施工時無需人工實時操控即可實現點對點精準噴涂。內壁噴涂機器人可通過算法自主調節與構件的槍距,確保涂裝穩定性。智能油漆用量控制系統則能依據工藝要求計算用量,從源頭減少材料浪費。

This painting production line integrates equipment such as outer wall spraying robots, inner wall spraying robots, intelligent tracked shuttle cars, and roller frames to work together. Among them, the outer wall spraying robot has functions such as autonomous programming, manual teaching, and automatic obstacle avoidance. It can customize the coating program according to the size of the components and achieve point-to-point precise spraying without real-time manual control during construction. The inner wall spraying robot can autonomously adjust the gun distance with the components through algorithms to ensure coating stability. The intelligent paint dosage control system can calculate the dosage based on process requirements, reducing material waste from the source.

此外,涂裝產線采用供氣與動力系統高度集成設計,實現全密閉保護,保障機器人連續24小時全負載作業,能夠大幅提高涂裝作業效率,為提升海洋油氣裝備可靠性打下堅實基礎。

In addition, the painting production line adopts a highly integrated design of gas supply and power system, achieving fully enclosed protection and ensuring continuous 24-hour full load operation of robots, which can greatly improve the efficiency of painting operations and lay a solid foundation for improving the reliability of marine oil and gas equipment.

本文由 機器人涂裝線 友情奉獻.更多有關的知識請點擊 http://www.qzxcdz.com/ 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the robot painting line For more related knowledge, please click http://www.qzxcdz.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

上一篇:自動噴粉線:噴涂自動線鏈條保養要點

下一篇:工業涂裝流水線的工藝流程

魯公網安備 37142502000144號

魯公網安備 37142502000144號