在基于工業4.0的涂裝生產線中如何做到清潔生產?

清潔生產的核心是“節能、降耗、減污、增效”。需要采用先進的工藝技術和材料,選用高端裝備,采取綜合利用和改善管理等措施,提高資源利用效率,從源頭削減污染,減少或避免涂裝生產線運行過程中污染物的產生和排放。總之,清潔生產不是把節能減排的重點放在末端,而是在生產全過程實施有效管理和控制。唯有不斷技術創新、改進設計、使用清潔的能源和原料,提升管理,受控排放,強化治理,才是“清潔生產”的手段。對于涂裝生產線而言,清潔生產的主體在于規劃設計和運行管理,這也是國內品牌涂裝生產線與國際先進水平的主要差距所在。

The core of clean production is "energy conservation, consumption reduction, pollution reduction, and efficiency improvement". It is necessary to adopt advanced process technology and materials, select high-end equipment, adopt comprehensive utilization and improved management measures, improve resource utilization efficiency, reduce pollution from the source, and minimize or avoid the generation and emission of pollutants during the operation of the coating production line. In short, clean production is not about focusing on energy conservation and emission reduction at the end, but about implementing effective management and control throughout the entire production process. Only continuous technological innovation, improved design, use of clean energy and raw materials, enhanced management, controlled emissions, and strengthened governance are the means of "clean production". For coating production lines, the main focus of clean production lies in planning, design, and operational management, which is also the main gap between domestic brand coating production lines and international advanced levels.

涂裝作業是汽車等許多產業的能耗及排放主體,各類設備密集的場合,廢水、廢氣、廢渣、噪音等集中產生地,長期以來,減污增效一直是涂裝生產線技術進步的動力,清潔生產的實施,在污染發生的全過程進行削減控制,改變過去“先污染后治理”的被動、滯后的污染控制手段,不僅大幅減小末端治理的費用,也有效避免末端治理的各種弊端,成為控制涂裝生產線環境污染的最有效手段。

Painting operations are the main source of energy consumption and emissions in many industries such as automobiles. In densely populated areas with various equipment, wastewater, exhaust gas, waste residue, noise, etc. are concentrated. For a long time, reducing pollution and increasing efficiency have been the driving force for technological progress in painting production lines. The implementation of clean production reduces and controls pollution throughout the entire process, changing the passive and lagging pollution control methods of "pollution first, treatment later" in the past. This not only significantly reduces the cost of end of pipe treatment, but also effectively avoids various drawbacks of end of pipe treatment, becoming the most effective means of controlling environmental pollution in painting production lines.

涂裝生產線的清潔生產模式包含自動化控制和智能控制技術、水性涂料、陰極電泳、機器人噴涂、逆流清洗等各種減量化模式。通過自動化控制和智能控制技術,在保證質量的基礎上,實行精準運行控制,定量化運行模式,有效降低運行參數,同時將循環技術、環保技術、節能技術和資源節約技術的應用效率得到極大的提高,提高利用率,實現節能環保,確保清潔生產模式的高效運行。

The clean production mode of the painting production line includes various reduction modes such as automation control and intelligent control technology, water-based coatings, cathodic electrophoresis, robot spraying, and reverse flow cleaning. Through automation control and intelligent control technology, precise operation control and quantitative operation mode are implemented on the basis of ensuring quality, effectively reducing operating parameters. At the same time, the application efficiency of cycle technology, environmental protection technology, energy-saving technology, and resource conservation technology is greatly improved, increasing utilization rate, achieving energy conservation and environmental protection, and ensuring the efficient operation of clean production mode.

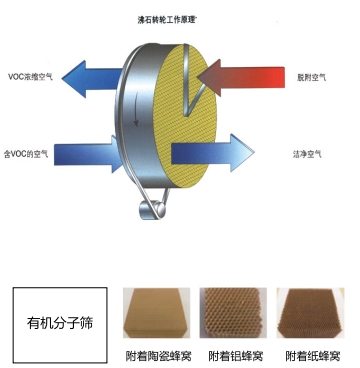

循環技術包括前處理藥液過濾分離技術、廢氣過濾回用、循環過濾清洗技術、污水處理循環利用,前處理藥液經過過濾分離,實現回用。環保技術包括漆霧干分離技術、濃縮焚燒技術、RTO技術等。節能技術包括變頻控制技術、LED照明、節能電機、熱電聯供、燃氣直燃加熱等。資源節約技術包括分離技術、太陽能利用、熱泵技術、機器人噴涂、廠區雨水收集系統等。綜合利用各項清潔生產技術,可將VOC排放降低80 %,廢水零排放,節能超過50 %。由此可以看出,清潔生產技術非某一項技術,而是各種技術的綜合集成有效應用,輔助以技術支持、培訓、指導和評價,達到最佳效果。

Circulating technology includes pre-treatment liquid filtration and separation technology, exhaust gas filtration and reuse, circulating filtration and cleaning technology, and sewage treatment and recycling technology. The pre-treatment liquid is filtered and separated to achieve reuse. Environmental protection technologies include paint mist dry separation technology, concentration incineration technology, RTO technology, etc. Energy saving technologies include variable frequency control technology, LED lighting, energy-saving motors, combined heat and power supply, gas direct combustion heating, etc. Resource conservation technologies include separation technology, solar energy utilization, heat pump technology, robot spraying, and rainwater collection systems in the factory area. By comprehensively utilizing various clean production technologies, VOC emissions can be reduced by 80%, zero wastewater discharge can be achieved, and energy savings can exceed 50%. From this, it can be seen that clean production technology is not a single technology, but a comprehensive integration and effective application of various technologies, assisted by technical support, training, guidance, and evaluation, to achieve the best results.

本文由 機器人涂裝線 友情奉獻.更多有關的知識請點擊 http://www.qzxcdz.com 真誠的態度.為您提供為全面的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from the robot painting line. For more related knowledge, please click http://www.qzxcdz.com Sincere attitude. We provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Please stay tuned

上一篇:機器人涂裝線廢氣處理工藝

下一篇:沸石轉輪在RTO系統中的應用

魯公網安備 37142502000144號

魯公網安備 37142502000144號