焊煙凈化器兩大類型揭秘,選對才能護好健康

焊接作為一種對金屬進行加熱的方式,在建筑、機械制造、汽車生產等行業中應用十分廣泛,不過與此同時也會產生大量有害氣體,特別是在通風條件欠佳的工廠車間里,焊接煙塵的濃度會大幅上升,會對工人的身體造成極大傷害。焊接煙塵粒子直徑細小、粘性較強、溫度較高,鼻毛和鼻粘膜無法起到阻擋作用,會直接侵入肺組織,引發塵肺病,要是進入血液還會導致中毒,像氫中毒和錳中毒就很常見。

Welding, as a method of heating metal, is widely used in industries such as construction, machinery manufacturing, and automobile production. However, it also generates a large amount of harmful gases, especially in poorly ventilated factory workshops where the concentration of welding fumes can increase significantly, causing great harm to workers' bodies. Welding smoke particles have small diameters, strong viscosity, and high temperatures. Nasal hair and mucous membranes cannot act as barriers and can directly invade lung tissue, causing pneumoconiosis. If they enter the bloodstream, they can also cause poisoning, such as hydrogen poisoning and manganese poisoning, which are very common.

一名工人一天能夠產生 60-150g 的焊接煙霧,粉塵量相當大。焊煙凈化器是一種新型的工業環保廢氣處理設備,通常應用于電焊、氬弧焊、二保焊以及其他焊接場所,以此達到保護環境和保障工人身體健康的目的。

A worker can generate 60-150g of welding smoke per day, with a considerable amount of dust. Welding smoke purifier is a new type of industrial environmental protection waste gas treatment equipment, usually used in welding, argon arc welding, secondary protection welding and other welding sites to protect the environment and ensure the health of workers.

焊煙凈化器主要分為移動式焊煙凈化器和集中式中央焊煙除塵器(以下簡稱集中式焊煙除塵器)兩個大類。那么,這兩者之間存在哪些區別呢?

Welding smoke purifiers are mainly divided into two categories: mobile welding smoke purifiers and centralized central welding smoke dust collectors (hereinafter referred to as centralized welding smoke dust collectors). So, what are the differences between these two?

移動式焊煙凈化器,是針對各類工業需求而設計的可移動高效凈化器,依據其工作臂的數量、系統方式以及清灰方式等,一般可以分為四大類,即單臂移動式焊煙凈化器、雙臂移動式焊煙凈化器、移動單臂脈沖焊煙凈化器、移動雙臂脈沖焊煙凈化器,適用于局部焊接煙塵的處理,可根據不同的工作地點和工作方式選用不同型號的活動臂管與排氣風機。移動式焊煙凈化器具有移動靈活平穩、體積小巧、煙塵捕獲率高、操作簡便、后續維修成本低等特點。

Mobile welding smoke purifier is a highly efficient purifier designed for various industrial needs. Based on the number of working arms, system mode, and dust cleaning method, it can generally be divided into four categories: single arm mobile welding smoke purifier, dual arm mobile welding smoke purifier, mobile single arm pulse welding smoke purifier, and mobile dual arm pulse welding smoke purifier. It is suitable for the treatment of local welding smoke and dust, and different models of movable arm pipes and exhaust fans can be selected according to different working locations and working methods. The mobile welding smoke purifier has the characteristics of flexible and stable movement, small size, high smoke and dust capture rate, easy operation, and low subsequent maintenance cost.

集中式焊煙除塵器采用除煙主機,借助管路與焊接臂相連接的方式來處理煙塵,適合用于焊接工位較多且相對集中的煙塵凈化場景。集中處理不會占用工廠空間,整體布局美觀,使用起來也很便利。凈化主機運用 PLC 控制,通過脈沖自動反吹清洗集塵,維護起來較為方便。與移動式焊煙凈化器相比,集中式焊煙除塵器的適應范圍更廣。

The centralized welding smoke dust collector adopts a smoke removal host, which is connected to the welding arm through pipelines to process smoke and dust. It is suitable for smoke and dust purification scenarios with many and relatively concentrated welding stations. Centralized processing does not occupy factory space, the overall layout is beautiful, and it is also very convenient to use. The purification host is controlled by PLC and automatically cleans and collects dust through pulse back blowing, making maintenance more convenient. Compared with mobile welding smoke purifiers, centralized welding smoke dust collectors have a wider range of adaptability.

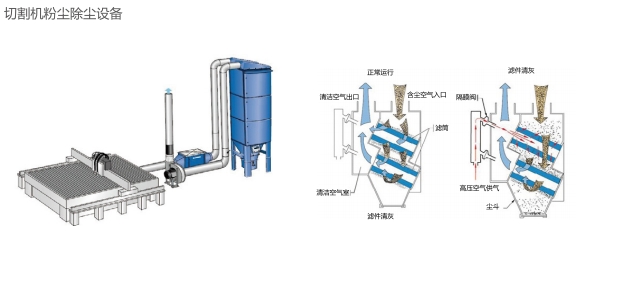

移動式焊煙凈化器適合焊接車間內工位較少且工件體積較小的焊煙收集處理,不適用于工位多、工件大或者機器人焊接手臂的工作環境。而集中式焊煙除塵器能夠利用頂吸罩對機器人焊接手臂產生的焊煙進行收集,也可以對焊接機器人工作站進行全封閉或半封閉的收集,此外還能對等離子切割、火焰切割等工藝過程中的煙塵進行凈化處理。集中式焊接除塵器更符合環保方面的要求。

The mobile welding smoke purifier is suitable for collecting and processing welding smoke in welding workshops with few workstations and small workpiece volumes, and is not suitable for working environments with multiple workstations, large workpieces, or robot welding arms. The centralized welding smoke dust collector can use a top suction hood to collect the welding smoke generated by the robot welding arm, and can also collect the welding robot workstation in a fully enclosed or semi enclosed manner. In addition, it can purify the smoke and dust during processes such as plasma cutting and flame cutting. Centralized welding dust collectors are more in line with environmental requirements.

集中式焊煙除塵器的特點:

Characteristics of centralized welding smoke dust collector:

配備全自動清灰系統,濾材清理更加方便快捷,不需要關停主機和進行其他操作。當濾筒表面的飽和阻力達到特定數值時,自動清潔功能就會啟動,并在主機工作過程中依次對各個濾筒單元進行單獨反吹清潔,確保集中式焊煙除塵器始終處于良好的工作狀態。

Equipped with a fully automatic dust cleaning system, filter material cleaning is more convenient and efficient, without the need to shut down the host or perform other operations. When the saturation resistance on the surface of the filter cartridge reaches a specific value, the automatic cleaning function will be activated, and each filter cartridge unit will be individually backwashed and cleaned during the operation of the main engine, ensuring that the centralized welding smoke dust collector is always in good working condition.

濾筒采用進口聚酯纖維過濾材料,過濾效率達到 99.5%,在正常使用條件下,濾筒的使用壽命比普通濾料要長得多,還可以選擇配置不同濾料的過濾筒,比如覆膜濾筒、阻燃濾筒等,以滿足對不同性質煙塵的清除或空氣過濾需求。

The filter cartridge is made of imported polyester fiber filter material, with a filtration efficiency of 99.5%. Under normal use conditions, the service life of the filter cartridge is much longer than that of ordinary filter media. It is also possible to choose filter cartridges with different filter media, such as membrane filter cartridges, flame retardant filter cartridges, etc., to meet the needs of removing different types of smoke and dust or air filtration.

濾筒的更換方式為抽取式,不需要使用任何輔助工具就能進行更換。設備的左、右側面都設有管路接口,用戶可以根據使用場合自由選擇。

The replacement method of the filter cartridge is extraction type, which can be replaced without the use of any auxiliary tools. The left and right sides of the device are equipped with pipeline interfaces, which users can freely choose according to their usage scenarios.

濾筒采用 15° 傾斜抽屜式安裝,能讓濾筒的拆換更加方便,而且集中式焊煙除塵器本體內不設置傳動部件,減少了維修所需的時間。

The filter cartridge adopts a 15 ° inclined drawer installation, which makes the removal and replacement of the filter cartridge more convenient. In addition, the centralized welding smoke dust collector does not have transmission components in the body, reducing the time required for maintenance.

所配置的高性能離心風機,吸風量較大,吸力強勁。可以通過控制板面上的數字儀表來觀察過濾筒的運行狀況。集中式焊煙除塵器對顆粒的凈化精度能夠達到 0.01μm,能夠極大地改善整體空間的煙塵污染情況。

The high-performance centrifugal fan configured has a large suction volume and strong suction power. The operation status of the filter cartridge can be observed through the digital instrument on the control panel. The centralized welding smoke dust collector can achieve a purification accuracy of 0.01 μ m for particles, which can greatly improve the overall smoke and dust pollution in the space.

本文由多工位焊煙除塵設備友情奉獻.更多有關的知識請點擊:http://www.qzxcdz.com我們將會對您提出的疑問進行詳細的解答,歡迎您登錄網站留言.

This article is dedicated to the automatic shot blasting machine and friendship For more information, please click: http://www.qzxcdz.com We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

上一篇:伸縮式噴漆房使用要怎么檢查呢?

下一篇:解析自動式拋丸機的多重作用與顯著特性

魯公網安備 37142502000144號

魯公網安備 37142502000144號